There are a few deciding factors when it comes to choosing hardwood flooring. One of the factors you may not have considered are the many types of wood cuts. Each cut adds its own unique appearance but also changes the performance under various common conditions. There are 4 different cutting options available. The most common among all species is plainsawn. Rift sawn, quarter sawn and live sawn are mostly produced with White Oak.

Plain Sawn

Plain Sawn

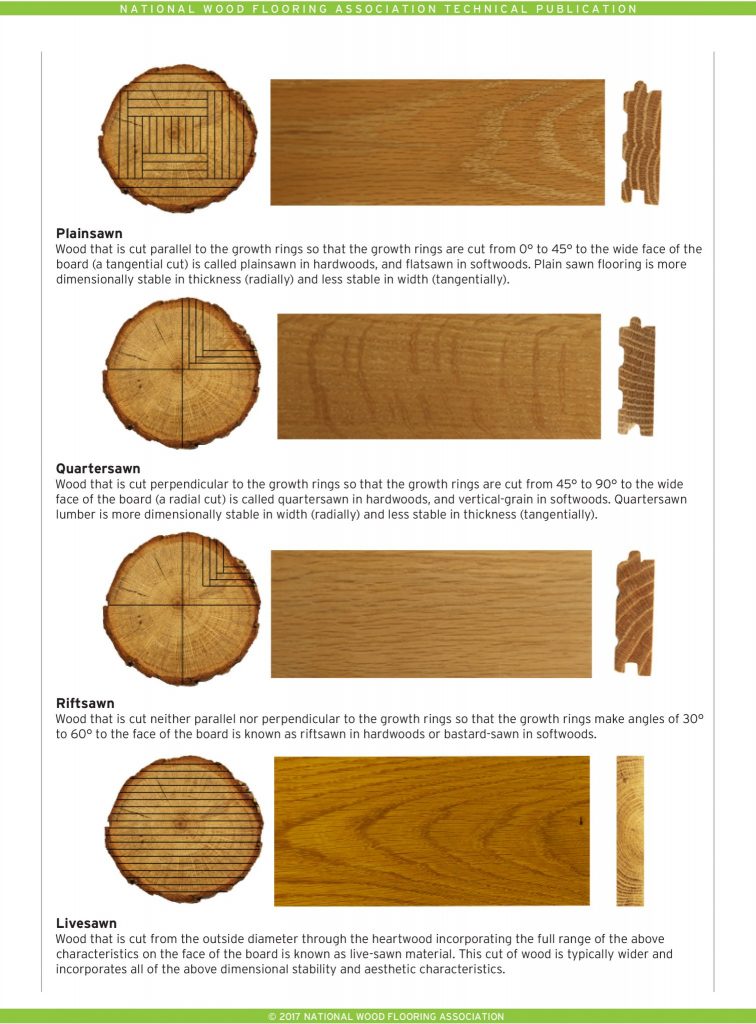

It is the most common cut used for flooring and most hardwood lumber products, also referred to as flatsawn. These boards have end grain with growth rings of 0 – 35 degrees to the surface that produce “cathedral” grain pattern. The performance of plain sawn flooring typically has the greatest amount of lateral movement across the width of the board during seasonal changes. Depending on species, most ¾” solid hardwood plain sawn flooring move twice as much across the width compared to rift and quarter sawn.

Quarter Sawn

These boards have end grain with growth rings of 60 – 90 degrees to the surface where the medullary rays of the lumber are split during the cutting process causing a unique “fleck” pattern to emerge. This pattern is mostly pronounced in White Oak flooring creating a very unique look.

Rift Sawn

These boards have end grain with growth rings of 45 degrees to the surface, producing a very linear grain pattern. This lumber is produced from the outer wedge of the quarter sawing process as the sawyer works his way from the inside to the outside of the wedge.

Rift and quarter sawn flooring typically has the most dimensionally stability as most of the movement is through the thickness of the board. This cut is best solid choice for radiant heat flooring.

Live Sawn

Also known as “thru cut” lumber, contains all three cuts (plain sawn, rift and quarter sawn) and has end grain with growth rings of 0 – 90 degrees to the surface. This cut creates a distinctive stunning look as it contains cathedral, fleck and linear grain patterns in a single board. To get the most apparent look, boards should be at least 6” wide and at Peachey we provide widths up to 16”!

This cut combines the performance characteristics of all three cuts. It’s generally more stable during seasonal changes and shrinks less on average compared to plain sawn due to greater percentage of rift and quarter sawn material in the cut.

NWFA Technical Illustration

NWFA.org

To see images of these various cuts, visit our White Oak page. Also, to learn more about other hardwood flooring decision factors, see our Hardwood Flooring 101.